The importance of car cooling system maintenance

- Share

- publisher

- Sally

- Issue Time

- Apr 18,2019

Summary

This article mainly talked about the symptom of sick cooling system and the function of engine cooling system.

The importance of car cooling system maintenance

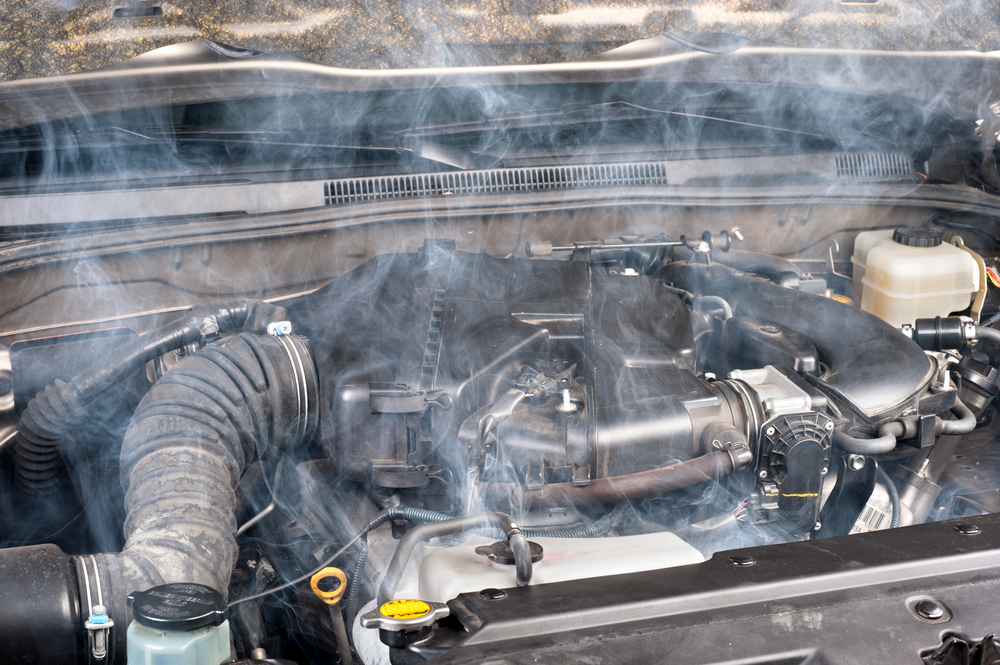

The summer is coming and temperatures is rising rapidly, knowing the symptoms of a sick cooling system are critical to your summer driving plans, since cooling system failure is a leading cause of vehicle breakdowns. The most noticeable symptoms are overheating, leaks, a sweet smell of antifreeze and repeatedly needing to add coolant.

Neglecting your cooling system can result in serious damage and even complete engine failure, which would put a sudden end to your summer road trip. If the

cooling system doesn’t receive regular maintenance, it’s not a question of whether it will fail, but rather when it will fail. Performing regular checkups of belts, hoses, the water pump and fluids will ensure your car remains properly cooled and healthy for many miles down the road.

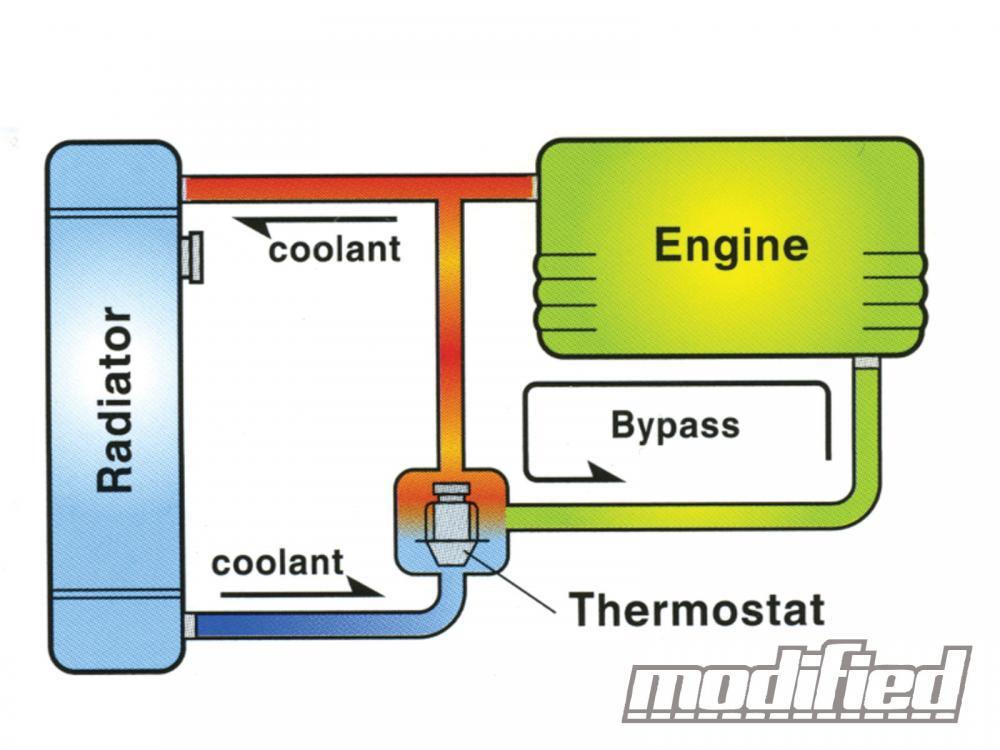

Engine coolant is pumped through the engine where it absorbs heat, through the radiator where it is cooled, and back to the engine. The fan moves air over the radiator, the hoses provide flexible connections between the stationary radiator and the vibration of the engine. The thermostat slows coolant flow until the engine is up to proper operating temperature. The heater core acts as a second radiator, heating the cabin with engine waste heat. The expansion tank—where additional coolant is monitored and added as needed— allows for expansion with temperature changes and seal the system against oxygen intrusion. It is a team, the coolant protecting the engine from over heating and corrosion, and the cooling system protecting the coolant from oxygen and excessive heat. Together, they maintain the engine at its most efficient temperature, whatever the environmental or operating conditions.

Modern engine run hot to burn clean. Operating temperatures have increased to reduce exhaust emissions and improve fuel economy. Today’s engines run on the borderline of overheating, with in-cylinder combustion temperatures around 2,000 °F. As fuel is burned in the engine, about one-third of the energy in the fuel is converted to kinetic energy for moving the vehicle, another third goes out the exhaust pipe, and the remaining third is removed by the cooling system. When no cooling is provided, metal parts warp and the pistons seize.

The primary job of the engine’s cooling system is to remove the heat that is generated during the combustion process. The coolant temperature can be well over 200 degrees and that heat has to go somewhere, otherwise engine components are going to start failing. The key parts of the cooling system remove the heat from the engine and automatic transmission and dispel it to the air outside. The water pump circulates coolant through the engine. The coolant absorbs heat and returns it to the radiator where heat is dissipated. The thermostat regulates the coolant temperature to keep it consistent for efficient engine operation.

A major factor that affects the replacement of cooling system parts is the frequency of regular maintenance, such as coolant changes. Motorists should consult their owner’s manual for specific recommendations about how often to change antifreeze and flush the coolant system. A coolant flush and fill is basic to cooling system maintenance as new antifreeze helps the engine run cooler and a flush removes dirt or sediment that could damage other cooling system parts.

The coolant level should be checked regularly at the reservoir and motorists are reminded to NEVER open a hot radiator cap. If the coolant is low, a 50/50 mix of approved antifreeze and distilled water should be added.

Motorists can also do a visual inspection of hoses, belts and the radiator to help identify cooling system problems before they escalate. Radiator leaks, bulging hoses or frayed and cracked belts are clues that the cooling system is in need of maintenance.

Additional signs of cooling system problems include the vehicle temperature gauge rising near the danger zone, coolant leaks, steam or hissing sounds under the hood or the district smell of an engine that’s running hot.

Finally, you should always follow the vehicle or engine manufacturer’s recommendations for antifreeze change intervals and cooling system maintenance. Suggested intervals range from 2 year/24,000 miles to 5 years/100,000 miles.

And the next news is about how to change the coolant and the difference between manual and machine exchanging the coolant.